View Larger Image

Ball valves are one of the valve types most widely used in different industries. The demand for the ball valve is still growing. Have you ever wondered how ball valves make impact to your applications.In this article, you will learn about the common components of a ball valve and their functions. What’s more, we will show you how a ball valve works to help you better understand it before you have one for your applications.

What is a Ball Valve?

As its name suggests, the ball valve has a ball-like disc that acts as a barrier when the valve is closed. Ball valve manufacturing companies often design the ball valve to be a quarter-turn valve but it can also be a rotatory kind when it controls or diverts the flow of media.

Ball valves are often used in applications that require tight sealing. They are known to have low-pressure drops. Its 90-degree turn makes it easy to operate even if the media has high volume, pressure or temperature. They are quite economical because of their long service life.

Ball valves are ideal for gases or liquids with little particles. These valves don’t work well with slurries as the latter easily damages the soft elastomeric seats. While they have throttling capacities, ball valves are not used as such because friction from the throttling can easily damage the seats too.

Parts of a Ball Valve

There are many variants of the ball valves, like 3-way ball valve and ball valves in different materials. In fact, 3-way ball valve working mechanism is also different from common ball valve. There are many ways to classify valves. Be as it may, there are seven valve components common to all valves.

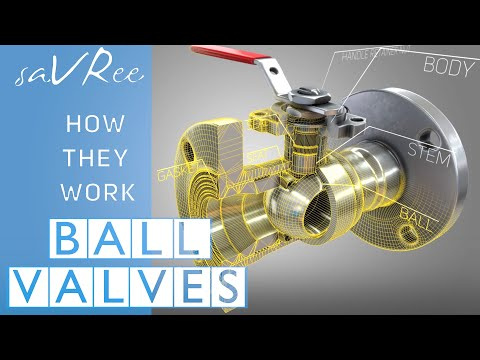

Body

The body is the framework of the entire ball valve. It acts as a barrier to the pressure load from the media so there is no transfer of pressure to the pipes. It holds all the components together. The body is connected to the piping via threaded, bolted or welded joints. Ball valves can be classified according to the type of body, often cast or forged.

Source: http://valve-tech.blogspot.com/

Stem

The opening or closing of the valve is provided by the stem. This is also what connects the ball disc to the lever, handle or actuator. The stem is the one that rotates the ball disc to open or close it.

Packing

This is the gasket that helps seal the bonnet and the stem. Many of the issues happen in this area so proper installation is important. Too loose, leakage happens. Too tight, movement of the stem is restricted.

Bonnet

The bonnet is the covering of the valve opening. This acts as the secondary barrier for pressure. The bonnet is what holds all the internal components together after these are inserted inside the valve body. Often made from the same material as the valve body, the bonnet can either be forged or cast.

Ball

This is the disc of the ball valve. Being the third most important pressure boundary, the pressure of the media acts against the disc when it is in the closed position. Ball discs are often made of forged steel or any durable material. Ball disc can either be suspended like in case of the floating ball valve, or it can be mounted like that of the trunnion-mounted ball valve.

Seat

Sometimes called the seal rings, this is where the ball disc rests. Depending on the design of the ball disc, the seat is either attached or not to the ball.

Actuator

Actuators are devices that create the rotation needed by the ball valve to open the disc. Oftentimes, these have a power source. Some actuators can be remotely controlled so valves still work even if these are located in remote or hard to reach areas.

Actuators can come as handwheels for manually operated ball valves. Some other types of actuators include solenoid types, pneumatic types, hydraulic types, and gears.

How Does a Ball Valve Work?

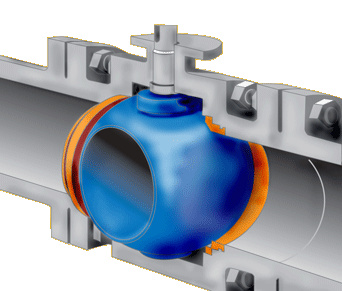

Generally speaking, the ball valve working mechanism works this way. Whether it is manually or actuator operated, some force moves the lever or handle to a quarter turn to open the valve. This force is transferred to the stem, moving the disc to open.

The ball disc turns and its hollowed side faces the flow of media. At this point, the lever is in the perpendicular position and the port to parallel in relation to the flow of media. There is a handle stop near the connection between the stem and bonnet to only allow a quarter-turn.

To close the valve, the lever moves back a quarter turn. The stem moves to turn the ball disc in the opposite direction, blocking the flow of media. The lever is in the parallel position and the port, perpendicular.

However, take note that there are three kinds of ball disc movement. Each of these has different working operations.

The floating ball valve has its ball disc suspended on the stem. There is no support at the bottom part of the ball so the ball disc partially relies on the internal pressure for the tight seal ball valves are known for.

As the valve closes, the upstream linear pressure from the media pushes the ball towards the cupped downstream seat. This provides a positive valve tightness, adding to its sealing factor. The downstream seat of the floating ball valve design carries the load of the internal pressure when the valve is closed.

The other kind of ball disc design is the trunnion mounted ball valve. This has a set of trunnions at the bottom of the ball disc, making the ball disc stationary. These trunnions also absorb the force from the pressure load when the valve closes so there is less friction between the ball disc and the seat. Sealing pressure is performed in both upstream and downstream ports.

When the valve closes, spring-loaded seats move against the ball which only rotates in its own axis. These springs push the seat tightly to the ball. Trunnion mounted ball types are suitable for applications that don’t need high pressure to move the ball to the downstream seat.

Lastly, the rising stem ball valve utilizes the tilt-and-turn mechanism. The ball disc wedges to the seat when the valve closes. When it opens, the disc tilts to remove itself from the seat and allow media flow.

What is a Ball Valve Used for?

# Oil

# Chlorine Manufacturing

# Cryogenic

# Cooling water and feed water system

# Steam

# Ship flowing systems

# Fire-safe systems

# Water filtration system

Conclusion

Understanding how the ball valve works means you can make intelligent decisions whether these valves are suitable for your needs. If you need to know more about ball valves, connect with XHVAL.

Post time: Feb-25-2022